Solution for the producing the Pallet(1200X1000X160 or 48 x 40″ ) 1.Image of the pallet

2.The mould Dimenson

SIZE L x W WEIGHT CAPACITY (LBS.) SHPG. WEIGHT FLOOR FORK RACK 48 x 40″ Black 30,000 5,000 2,000 50 lbs.

3.The mould Info

Height: 6 1/4″

Fork Opening: 3.6″

Additional dimensions in the Instructions.

MATERIAL: HDPE (High Density Polyethylene)

FEATURES: 4-way access / Waterproof

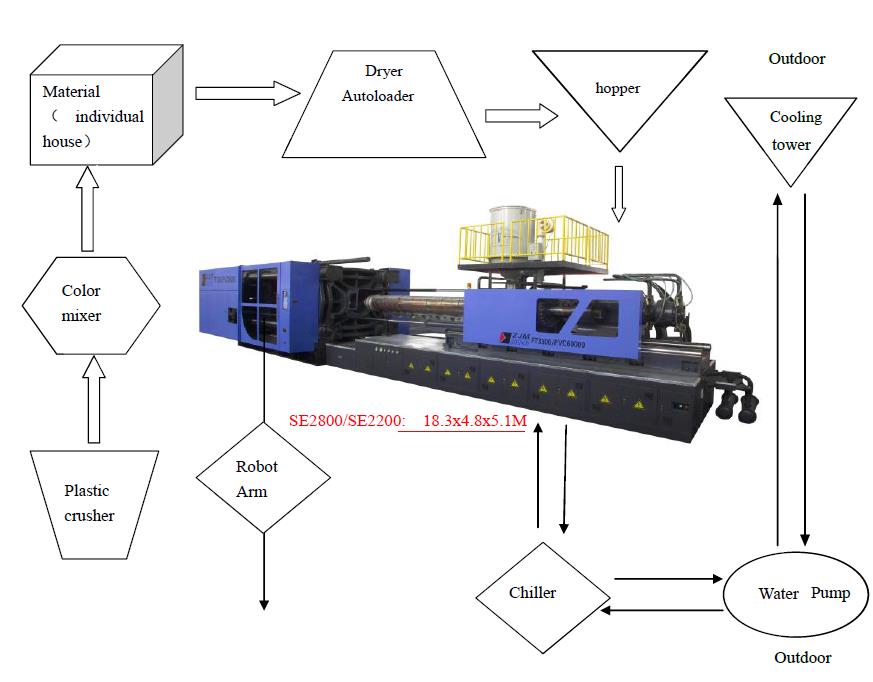

4. Sketch map for the production

Note :

The foundation must be inspected by professional civil engineer.

Required size of workshop: above 600 square meters.

Recommended height of workshop: mini 8 m (higher if robot is applicable)

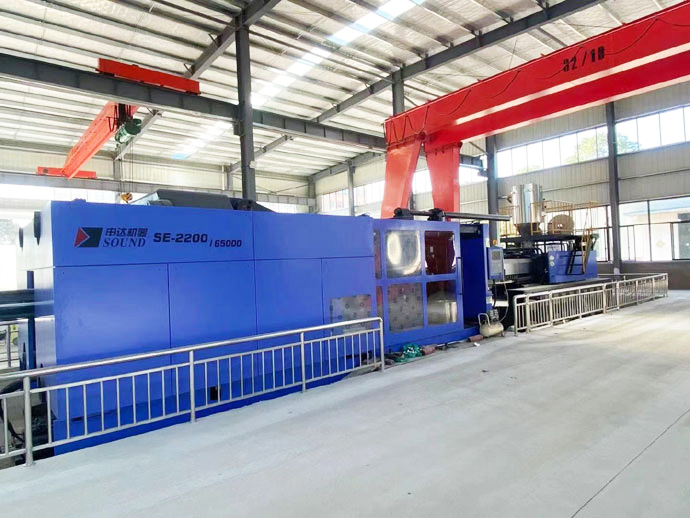

5.Injection molding machine needed for the pallet mould and for its cover

Specification of SE2800/ SE2200

Part Item Technical Parameters Injection Unit Screw dia. mm 185 195 Screw L/D ratio 22 22 Theoretical injec. V. cm3 24192 29850 Injection Capacity (PS) g 22075 27238 Injection rate g/s 1700 1700 Plasticizing Capacity g/sec 223 248 Injection pressure MPa 140 125 Screw rotation speed r/min 0~70 Clamping Unit Clamping force kN 22000 Space between tie-bar mm 1800×1600 Clamp stroke mm 1850 Max.Mold Height mm 1700 Min.Mold Height mm 700 Ejector Force KN 500 Ejector Stroke mm 400 Ejector Number Pc 25

6.Anxillary equipments:

①hopper-dryer

Model SHD-800KG Capacity (kg) 800 Dry heater power(kw) 30 Blower Power(W) 1100 External size(mm) 1380 X 1150 X 2250

②autoloader

Model SAL-4HP Conveying capacity(kg/hr) 600 Volume of hopper(Kg) 12 Inside diameter of conveying pipe φ51 External size(mm) (L W H) 450X380X800 Weight(kg) 65+12

③Mixer

Model SG-600F Power(KW) 15 Quantity of rotaing blades 18 Quantity of fixed blades 4 Screen size Φ12 Weight(kg) 1300 Max.breaking capacity(kg/hr) 350-450 Size of feeding inlet(MM) 320X600 External size 1200X1110X1690

Specification SL-20W Cooling capacity Kcal/h 51600 Compressor All-closed vorticity Compressor input power HP 20 Refrigerant Filling quantity kg 10 Compressor KW 2.2 Max flow rate of chilled water L/MIN 350 Flow water inlet and outlet pipe ″ 2 Size length MM 1800 Size width MM 950 Size height MM 1700 Weight Kg 600

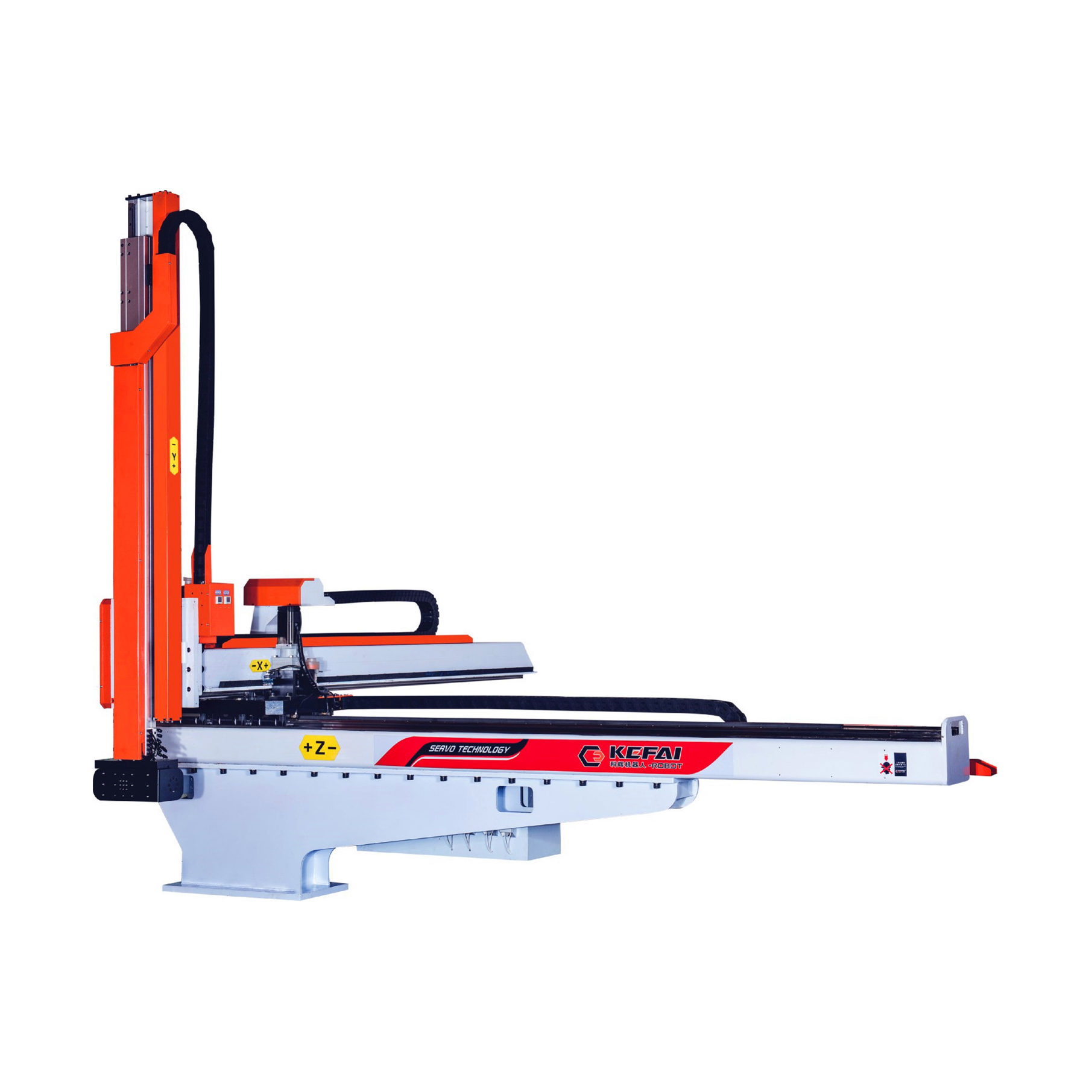

Model Unit KAW+A2400 KAW+A2800 KAW+A3300 Arm type Double section Vertical stroke mm 2400 2800 3300 Crosswise stroke mm 3000 3200 3500 Swing stroke mm 3800 4200 4500 Drive system X Y Z A Servo motor Swing angel degree 270 270 270 Max loading(with tool) kg 20 25 30 Min take time sec 5 6 8 Dry cycle time sec 16 18 20 Working air pressure kgf/c㎡ 5-7 5-7 5-7 Air consumption NL/cycle 25 30 30 Power consumption KVA 1.5 1.8 1.8 Power AC 220V 50-60HZ 220V 50-60HZ 220V 50-60HZ Net weight Kg 900 1200 1500 Gross weight Kg 950 1250 1550 Product size m 3.80*3.00*2.70 4.20*3.20*3.10 4.50*3.50*3.60 Packing size m 3.85*3.05*2.80 4.25*3.25*3.20 4.55*3.55*3.70 Applicable IMM model T 2000-2400 2800-3000 4000

7.The quotation of Equipment needed above

PRICE: FOB NINGBO

DESCRIPTION Photo QTY/Set Unit price (USD) AMOUNT (USD) Model :SE2800 /SE2200 Vtt : 380V, 3 Phase, 50HZ1 524,618 524,618 The mould for pallet 1 95 , 522 95 , 522 Hopper-dryer : SHD-800KG Vtt : 380V, 3 Phase, 50HZ 1 2500 2500 Autoloader: SAL-4HP Vtt : 380V, 3 Phase, 50HZ 1 900 900 Mixer: SSM-300Kg Vtt : 380V, 3 Phase, 50HZ 1 1800 1800 Plastic Crusher: SG-600F Vtt : 380V, 3 Phase, 50HZ 1 2600 2600 Water-typed chiller: SL-20W Vtt : 380V, 3 Phase, 50HZ 1 6500 6500 Robot Arm Vtt : 380V, 3 Phase, 50HZ 1 14,560 14,560 Total: 649,000USD

8.Technological process Stage Time(pallet) Time(its cover) Plasticizing(cooling time included) 82S 38s Injection(holding included) 15S 4s Mould clamping(ejection included) 35S 30s Cycle time : 132S 72s

9.Production and power consumption Item pallet Its cover ◆Cycle time 132S 72s ◆Daily output(8hours) 218PC 400PC ◆Power consumption (including the ancillaries) 106kWh/H 106kWh/H ◆Average power consumption 3.8kWh/PC 2.12kWh/PC

Note : The description as above is just estimated value . The actual value depends on the type of material、difference of mould、configuration of auxiliary.VIDEO